-

GP-1027GEOPOL- GP-1027-Polyol is a formulated, CFC & HCFC free Polyether Polyol blended with zero ODP blowing agent. This formulated performance Polyol is specially developed for the insitu application, Solar Water Heater, Deep freezer & other general Insulation purpose. This formulated Polyol is to be used along with GEONATE- GP-1027-Isocyanate / other equivalent Isocyanate. This formulated Polyol gives excellent flow ability, even density distribution, good dimensional stability and Low thermal conductivity Properties.

Application

-

TYPICAL COMPONENT PROPERTIES

Properties Unit Polyol Isocyanate OH Values mg KOH/gm 340 + 25 - Viscosity @ 25o C cps 500 + 100 200 + 20 Specific Gravity - 1.0 - 1.15 1.2 – 1.3 NCO content % - 30.9 - 32.1 -

RECOMMENDED PROCESS CONDITIONSGP-1023/PL system can be processed by High pressure & Low Pressure machine. A Component temperature in between 25oC-30oC is recommended.

Componet Unit limit Polyol pbw 100 Isocyanate pbw 100 - 125 -

TYPICAL REACTION CHARACTERSTICS

Reaction Profile Units Cup Test (at 210C) Cream Time sec 10 - 12 Gel Time sec 80 - 90 Tack Free Time sec 100 - 110 Free Rise Density Kg/m3 24 - 25 -

PHYSICAL FOAM PROPERTIES

Testing Parameters Test Standard Unit Value Overall applied Density ASTM D-1622-63 kg/m3 38-40 Compressive Strength ASTM D-1621-94 kg/cm2 >1 Thermal Conductivity ASTM C-518-76 kcal/mh0 C <0.03 Closed Cell Content ASTM D-2856-65 % >95 Dimensional Stability ASTM D-2126-94 % <1 -

HANDLING AND STORAGEShould be kept in original sealed drums in a dry place at the recommended temperature.

# Units Polyol Isocyanate Storage temperature 0C 15-25 15-25 Storage Stability months 3 6 -

SAFETY CONSIDERATIONSMaterial safety data Sheet are available to help customers satisfy their own handling, safety and disposal needs and those that may be required by locally applicable health and safety regulations.MSD sheets are updated regularly therefore, please request and review the most current MSD sheet before handling or using the product.

Rigid Polyol

-

GP-1005/TGEOPOL- GP-1005/T Polyol is a formulated, CFC & HCFC free Polyether Polyol blended with zero ODP blowing agent. This formulated performance Polyol is specially developed for Thermo ware applications like water bottles, casseroles, water jugs, ice boxes and plastic pallets etc. This formulated Polyol is to be used along with GEONATE-GP-1005/T- Isocyanate / other equivalent Isocyanate. This formulated Polyol gives excellent flow ability, even density distribution, good dimensional stability & Low thermal conductivity Properties.

Application

-

TYPICAL COMPONENT PROPERTIES

Properties Unit Polyol Isocyanate OH Values mg KOH/gm 340 + 25 - Viscosity @ 25o C cps 500 + 100 200 + 20 Specific Gravity - 1.0 - 1.15 1.2 – 1.3 NCO content % - 30.9 - 32.1 -

RECOMMENDED PROCESS CONDITIONSGP-1023/PL system can be processed by High pressure & Low Pressure machine. A Component temperature in between 25oC-30oC is recommended.

Componet Unit limit Polyol pbw 100 Isocyanate pbw 100 - 125 -

TYPICAL REACTION CHARACTERSTICS

Reaction Profile Units Cup Test (at 210C) Cream Time sec 10 - 12 Gel Time sec 80 - 90 Tack Free Time sec 100 - 110 Free Rise Density Kg/m3 24 - 25 -

PHYSICAL FOAM PROPERTIES

Testing Parameters Test Standard Unit Value Overall applied Density ASTM D-1622-63 kg/m3 38-40 Compressive Strength ASTM D-1621-94 kg/cm2 >1 Thermal Conductivity ASTM C-518-76 kcal/mh0 C <0.03 Closed Cell Content ASTM D-2856-65 % >95 Dimensional Stability ASTM D-2126-94 % <1 -

HANDLING AND STORAGEShould be kept in original sealed drums in a dry place at the recommended temperature.

# Units Polyol Isocyanate Storage temperature 0C 15-25 15-25 Storage Stability months 3 6 -

SAFETY CONSIDERATIONSMaterial safety data Sheet are available to help customers satisfy their own handling, safety and disposal needs and those that may be required by locally applicable health and safety regulations.MSD sheets are updated regularly therefore, please request and review the most current MSD sheet before handling or using the product.

-

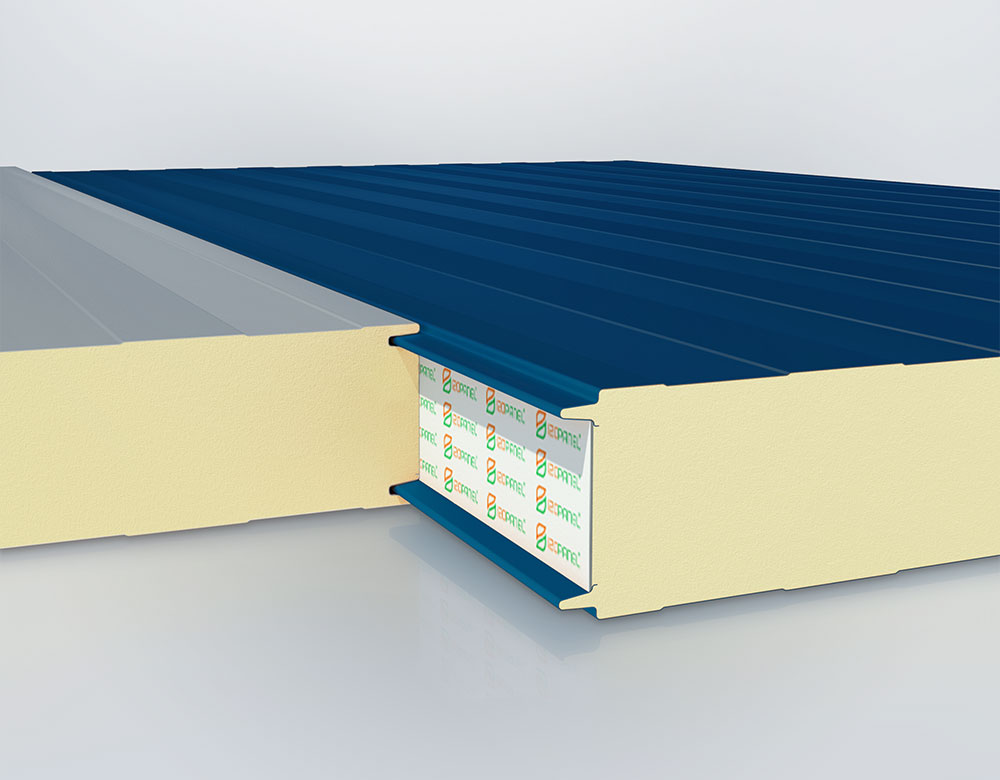

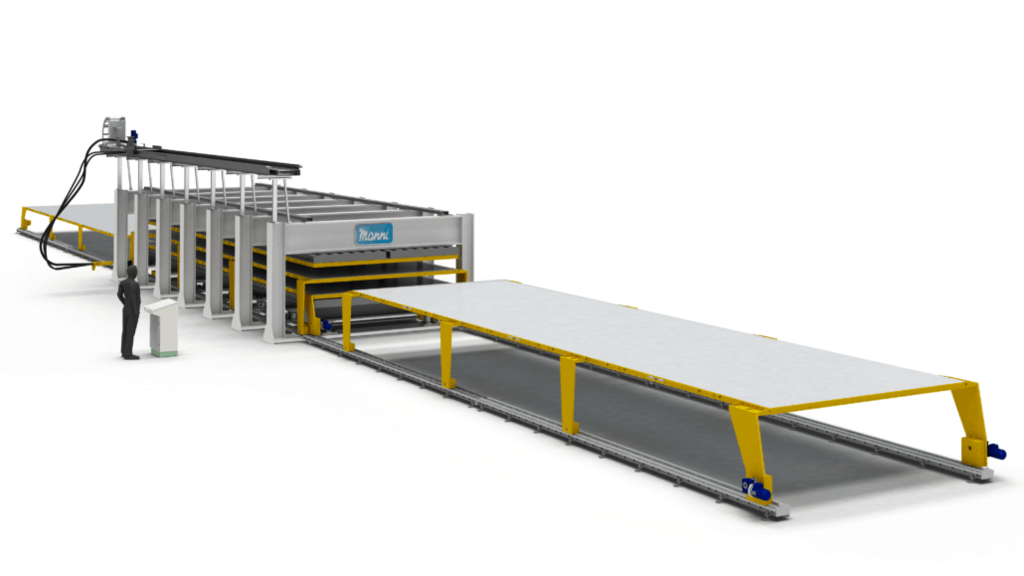

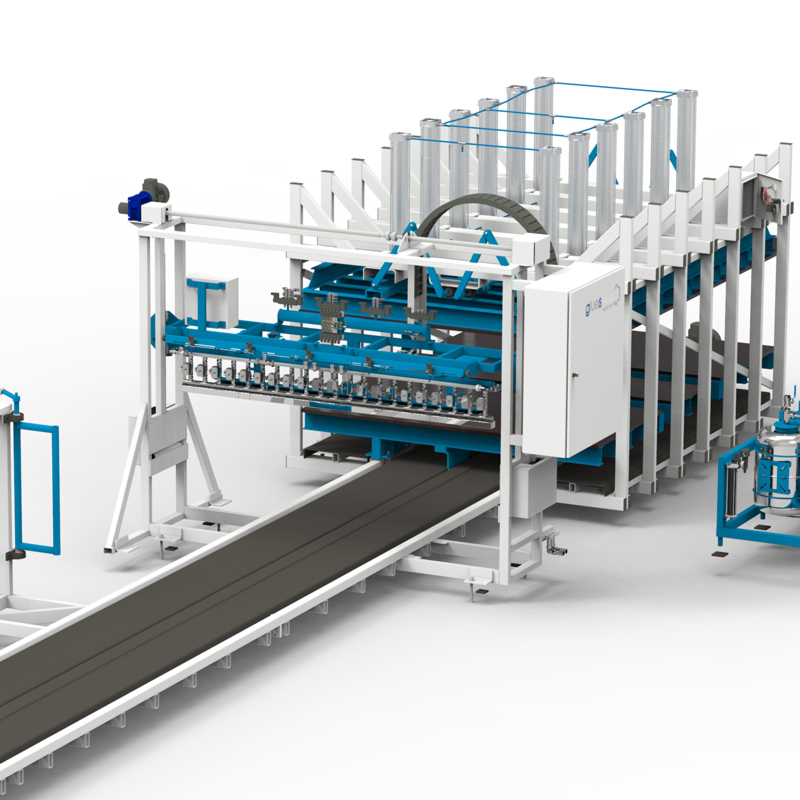

GP-1023/PLGP-1023/PL-Polyol is a formulated, CFC & HCFC free Polyether Polyol blended with zero ODP blowing agent. This formulated performance Polyol is specially developed for discontinuous panel & other general Insulation purpose. This formulated Polyol is to be used along with GP-1023/PL-Isocyanate / other equivalent Isocyanate. This formulated Polyol gives excellent flow ability, even density distribution, good dimensional stability and Low thermal conductivity.

Application

-

TYPICAL COMPONENT PROPERTIES

Properties Unit Polyol Isocyanate OH Values mg KOH/gm 340 + 25 - Viscosity @ 25o C cps 500 + 100 200 + 20 Specific Gravity - 1.0 - 1.15 1.2 – 1.3 NCO content % - 30.9 - 32.1 -

RECOMMENDED PROCESS CONDITIONSGP-1023/PL system can be processed by High pressure & Low Pressure machine. A Component temperature in between 25oC-30oC is recommended.

Componet Unit limit Polyol pbw 100 Isocyanate pbw 100 - 125 -

TYPICAL REACTION CHARACTERSTICS

Reaction Profile Units Cup Test (at 210C) Cream Time sec 10 - 12 Gel Time sec 80 - 90 Tack Free Time sec 100 - 110 Free Rise Density Kg/m3 24 - 25 -

PHYSICAL FOAM PROPERTIES

Testing Parameters Test Standard Unit Value Overall applied Density ASTM D-1622-63 kg/m3 38-40 Compressive Strength ASTM D-1621-94 kg/cm2 >1 Thermal Conductivity ASTM C-518-76 kcal/mh0 C <0.03 Closed Cell Content ASTM D-2856-65 % >95 Dimensional Stability ASTM D-2126-94 % <1 -

HANDLING AND STORAGEShould be kept in original sealed drums in a dry place at the recommended temperature.

# Units Polyol Isocyanate Storage temperature 0C 15-25 15-25 Storage Stability months 3 6 -

SAFETY CONSIDERATIONSMaterial safety data Sheet are available to help customers satisfy their own handling, safety and disposal needs and those that may be required by locally applicable health and safety regulations.MSD sheets are updated regularly therefore, please request and review the most current MSD sheet before handling or using the product.

-

GP-2007/LPTGEOPOL- GP-2007/LPT Polyol is a formulated, CFC & HCFC free Polyether Polyol blended with methyl formate as a blowing agent. This formulated performance Polyol is specially developed for Thermoware applications like casseroles and plastic pallets etc. This formulated Polyol is to be used along with GEONATE-GP-2007/LPT-Isocyanate / other equivalent Isocyanate. This formulated Polyol gives excellent flow ability, even density distribution, good dimensional stability & Low thermal conductivity Properties.

Application

-

TYPICAL COMPONENT PROPERTIES

Properties Unit Polyol Isocyanate OH Values mg KOH/gm 340 + 25 - Viscosity @ 25o C cps 500 + 100 200 + 20 Specific Gravity - 1.0 - 1.15 1.2 – 1.3 NCO content % - 30.9 - 32.1 -

RECOMMENDED PROCESS CONDITIONSGP-1023/PL system can be processed by High pressure & Low Pressure machine. A Component temperature in between 25oC-30oC is recommended.

Componet Unit limit Polyol pbw 100 Isocyanate pbw 100 - 125 -

TYPICAL REACTION CHARACTERSTICS

Reaction Profile Units Cup Test (at 210C) Cream Time sec 10 - 12 Gel Time sec 80 - 90 Tack Free Time sec 100 - 110 Free Rise Density Kg/m3 24 - 25 -

PHYSICAL FOAM PROPERTIES

Testing Parameters Test Standard Unit Value Overall applied Density ASTM D-1622-63 kg/m3 38-40 Compressive Strength ASTM D-1621-94 kg/cm2 >1 Thermal Conductivity ASTM C-518-76 kcal/mh0 C <0.03 Closed Cell Content ASTM D-2856-65 % >95 Dimensional Stability ASTM D-2126-94 % <1 -

HANDLING AND STORAGEShould be kept in original sealed drums in a dry place at the recommended temperature.

# Units Polyol Isocyanate Storage temperature 0C 15-25 15-25 Storage Stability months 3 6 -

SAFETY CONSIDERATIONSMaterial safety data Sheet are available to help customers satisfy their own handling, safety and disposal needs and those that may be required by locally applicable health and safety regulations.MSD sheets are updated regularly therefore, please request and review the most current MSD sheet before handling or using the product.

-

GP-1226/PIRGEOPOL- GP-1226/PIR-Polyol is a formulated, CFC & HCFC free Polyether Polyol blended with zero ODP blowing agent. This formulated performance Polyol is specially developed for the Panel, Block, cabins & other general Insulation purpose. This formulated Polyol is to be used along with GEONATE-GP-1226-Isocyanate / other equivalent Isocyanate. This formulated Polyol gives excellent flow ability, even density distribution, good dimensional stability and Low thermal conductivity with good fire retardant Properties & corresponds to building material class B2 as per DIN 4102 Part 1.

Application

-

TYPICAL COMPONENT PROPERTIES

Properties Unit Polyol Isocyanate OH Values mg KOH/gm 340 + 25 - Viscosity @ 25o C cps 500 + 100 200 + 20 Specific Gravity - 1.0 - 1.15 1.2 – 1.3 NCO content % - 30.9 - 32.1 -

RECOMMENDED PROCESS CONDITIONSGP-1023/PL system can be processed by High pressure & Low Pressure machine. A Component temperature in between 25oC-30oC is recommended.

Componet Unit limit Polyol pbw 100 Isocyanate pbw 100 - 125 -

TYPICAL REACTION CHARACTERSTICS

Reaction Profile Units Cup Test (at 210C) Cream Time sec 10 - 12 Gel Time sec 80 - 90 Tack Free Time sec 100 - 110 Free Rise Density Kg/m3 24 - 25 -

PHYSICAL FOAM PROPERTIES

Testing Parameters Test Standard Unit Value Overall applied Density ASTM D-1622-63 kg/m3 38-40 Compressive Strength ASTM D-1621-94 kg/cm2 >1 Thermal Conductivity ASTM C-518-76 kcal/mh0 C <0.03 Closed Cell Content ASTM D-2856-65 % >95 Dimensional Stability ASTM D-2126-94 % <1 -

HANDLING AND STORAGEShould be kept in original sealed drums in a dry place at the recommended temperature.

# Units Polyol Isocyanate Storage temperature 0C 15-25 15-25 Storage Stability months 3 6 -

SAFETY CONSIDERATIONSMaterial safety data Sheet are available to help customers satisfy their own handling, safety and disposal needs and those that may be required by locally applicable health and safety regulations.MSD sheets are updated regularly therefore, please request and review the most current MSD sheet before handling or using the product.

-

GEOPOL- GP-1035/BH-Polyol is a formulated, CFC & HCFC free Polyether Polyol blended with zero ODP blowing agent. This formulated performance Polyol is specially developed for block, insitu and other general insulation purpose. This formulated Polyol is to be used along with GEONATE-GP-1035/BH-Isocyanate / other equivalent Isocyanate. This formulated Polyol gives excellent flow ability, even density distribution, good dimensional stability and Low thermal conductivity Properties.

Application

-

TYPICAL COMPONENT PROPERTIES

Properties Unit Polyol Isocyanate OH Values mg KOH/gm 340 + 25 - Viscosity @ 25o C cps 500 + 100 200 + 20 Specific Gravity - 1.0 - 1.15 1.2 – 1.3 NCO content % - 30.9 - 32.1 -

RECOMMENDED PROCESS CONDITIONSGP-1023/PL system can be processed by High pressure & Low Pressure machine. A Component temperature in between 25oC-30oC is recommended.

Componet Unit limit Polyol pbw 100 Isocyanate pbw 100 - 125 -

TYPICAL REACTION CHARACTERSTICS

Reaction Profile Units Cup Test (at 210C) Cream Time sec 10 - 12 Gel Time sec 80 - 90 Tack Free Time sec 100 - 110 Free Rise Density Kg/m3 24 - 25 -

PHYSICAL FOAM PROPERTIES

Testing Parameters Test Standard Unit Value Overall applied Density ASTM D-1622-63 kg/m3 38-40 Compressive Strength ASTM D-1621-94 kg/cm2 >1 Thermal Conductivity ASTM C-518-76 kcal/mh0 C <0.03 Closed Cell Content ASTM D-2856-65 % >95 Dimensional Stability ASTM D-2126-94 % <1 -

HANDLING AND STORAGEShould be kept in original sealed drums in a dry place at the recommended temperature.

# Units Polyol Isocyanate Storage temperature 0C 15-25 15-25 Storage Stability months 3 6 -

SAFETY CONSIDERATIONSMaterial safety data Sheet are available to help customers satisfy their own handling, safety and disposal needs and those that may be required by locally applicable health and safety regulations.MSD sheets are updated regularly therefore, please request and review the most current MSD sheet before handling or using the product.